Product Design in Sheffield - Our Industrial City

- Jonny Taylor

- Jan 24, 2024

- 3 min read

Updated: Jun 20

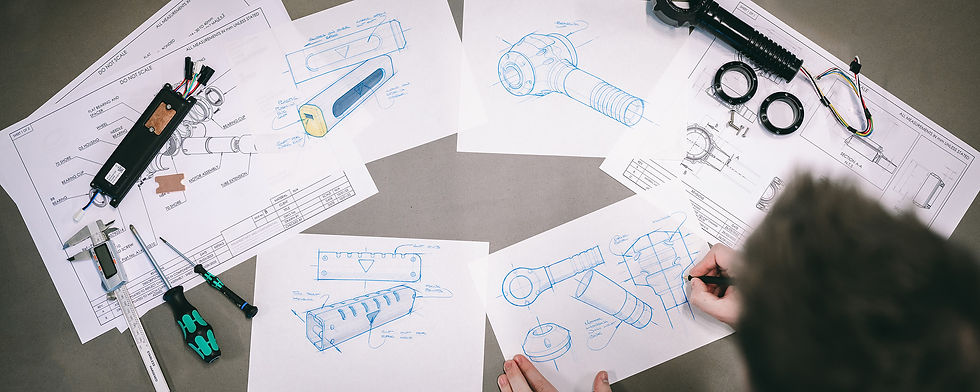

2024 is an exciting year here at JAM and we want to start sharing what we get up to in our studio.

Sheffield is an incredible place for designing and manufacturing and where we have chosen to base our product design agency.

Our studio is based in the Harland Works which is the oldest steel framed building in Sheffield and was once the home of Henry Stones, manufacturer of Steel and Files. The area we are in is known as Little Sheffield and we are surrounded by lots of historic industrial buildings such as Portland Works and Stag Works. These big industrial works once housed lots of independent businesses centred around the steel industry. The individual workshops produced tools, knives, and cutlery and these independent craftsmen were known as Little Mesters. This is derived from the Sheffield dialect for Little Masters.

Today these big industrial buildings are still home to lots of Little Masters; independent, creative people all with different skills and trades. As designers, this means that we are surrounded by people with the knowledge and skills to make an incredible range of products. You will often find us poking around in another workshop, intrigued by what they are making or asking them if they can make something for us!

In our building, we have a violin bow maker, a furniture maker, two architects, a film producer, graphic designers, tattoo artists, jewellery makers, and more. Next door, we have Steve the Stone Mason, knife makers, cutlery makers, dressmakers, musicians, Mamnick UK-made clothing, Lovely Rita's Bakehouse, Puck and Pollen, and a recording studio. Behind us, we have Tietzsch Guitars, Portland Works Photography Studio, Michael May Knives, Stuart Mitchell Knives, Sheffield Hackspace, Bailey of Sheffield, and Retribe just to name a few.

This community of manufacturers in Little Sheffield and across the city means that we have access to a network of people who can help bring ideas to life. As well as utilising our in-house 3D printers for prototyping, we work closely with manufacturers across the city to turn concepts into working prototypes and production-ready products.

Many of the manufacturing and assembly factories that we use are in the Far East but having access to skills and manufacturing at home means that we can discuss the pros and cons of making products abroad and give our clients the option to keep all or part of their manufacturing in the UK.

We recently designed and machined aluminium components for a UK-based client. It turned out to be cheaper and quicker to make them in Sheffield at a specialist machine shop than it would have been to use a machine shop in China or Taiwan and ship them to the UK. The client was able to easily visit the machine shop and keep a close eye on the quality during the initial production run.

Last week we visited a spring maker in Sheffield to enquire about a spring for a prototype and we walked away with a custom spring made there and then, a quote for a production run and another useful manufacturing contact in the City.

This local manufacturing knowledge is what makes Sheffield the best place for us to be as industrial designers. The people we meet through design are the people who inspire us and keep our work exciting.

Here’s to the makers!