3D Printing & Industrial Design in Sheffield: TCT 3Sixty

- Jun 6, 2025

- 2 min read

Updated: Jun 20, 2025

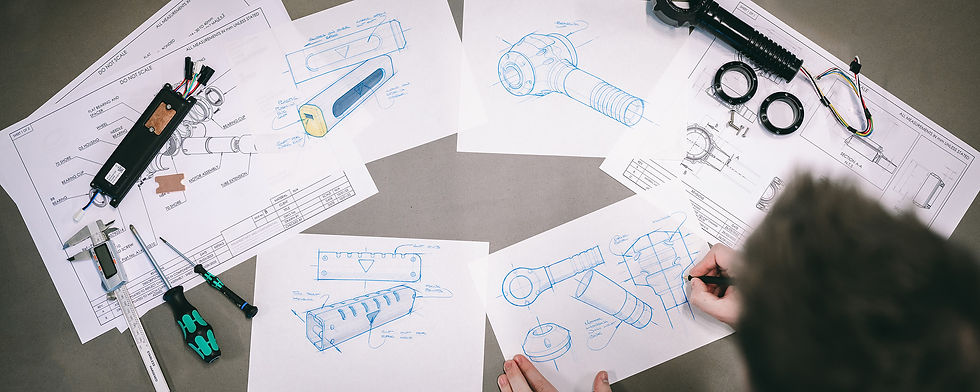

On the 4th of June, the JAM team attended TCT 3Sixty at the NEC, a leading UK trade show for industrial 3D printing and additive manufacturing. As a product design consultancy based in Sheffield, it was a great opportunity to take a trip out of the studio and explore the latest advancements and see how they could influence our industrial design processes back at home.

From innovative software and machines to advanced materials and finishing techniques, the show offered plenty of inspiration for how we can elevate our services and deliver even more value to our clients.

Catching Up With Familiar Faces

A big part of the visit was touching base with some of our existing partners. I spent time with the team at Solid Print 3D, who we've previously sourced 3D printers and materials from. They continue to impress with their range and support.

We also used the trip to catch up with several of our manufacturing partners, based in the UK and abroad. We talked about how we can collaborate on future projects together as well as how current and past projects have progressed. Having our network of trusted partners makes the transition from a CAD file, to a final product a great deal smoother.

Innovation on Display

The breadth of different technologies on display was fantastic. Machines like the Piocreat G-Series show how far large-format 3D printing has come. Not just in size, but also in speed and precision.

It was great to see such detailed, full-scale prints right on the stand, including architectural models, mechanical components, and artistic sculptures. You really get a feel for the tangible impact additive manufacturing is having across sectors.

Another highlight was seeing the improvements in, and increased accessibility to metal additive manufacturing. We had a great talk with the team from Apex Tech after being drawn into their stand by their display of these Deviate bike components.

Materials Matter: A Closer Look at Finishing Options

Another highlight was seeing the breadth of material and finishing options offered by companies like 3DPRINTUK. From Nylon PA12 to flexible TPU, it’s clear that the industry is no longer just about rapid prototyping, it’s about quickly creating real, functional parts ready for end use.

Bonus: My 3D Scan Moment

For a bit of fun, I (Matt) even had a 3D scan of my head done at one of the stands! It’s a fun reminder of just how versatile these technologies are, not just for engineering, but for entertainment, healthcare, and more.

Takeaways and Looking Ahead

Attending TCT 3Sixty left us feeling inspired by the pace of innovation and excited about the practical applications available. It reaffirmed how important it is to stay up to date with the latest in technological advancements, not just for our own workflows, but for the added value we can pass on to our clients.

If you're exploring how you or your company can benefit from additive manufacturing or if you are looking for support with your next industrial design project in Sheffield or further a field, feel free to get in touch, we’d love to chat.

Alternatively, why not see how we integrate the 3D printers that we operate in our studio in Sheffield into our product design services.